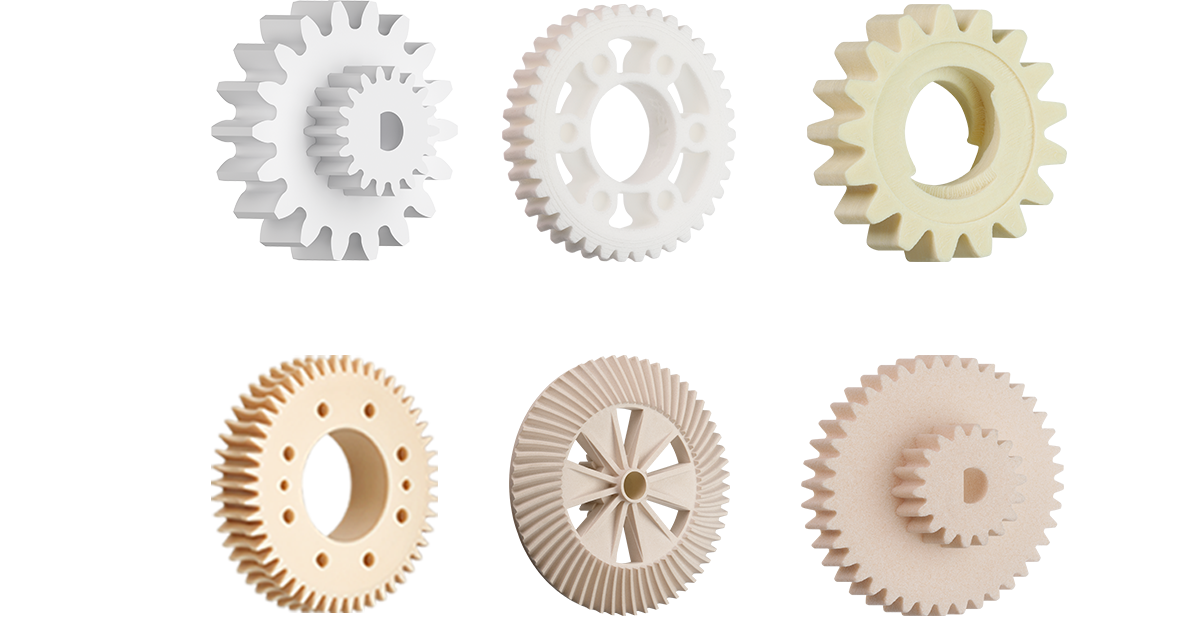

You have the idea, we make it a reality! Simply upload your file (e.g. CAD) or our checklist and describe the special features of your application. Your data will be treated confidentially, of course.

Customised and cost-effective: your polymer bearing in the required shape, quantity and material

High-volume production: efficient, flexible, scaleable

After receiving your CAD data, we will contact you within just a few hours to make you an interactive offer with the manufacturing method recommended for your component. High-volume production in our in-house injection moulding service department is also possible.

Custom-made components, no minimum order quantity

Each method used to manufacture individual customised solutions has its specific advantages and disadvantages. From 3D printing to manufacturing from bar stock, urgent enquiries without a minimum order quantity. We help you to choose the right manufacturing method for your application.

Prototypes and test samples for your application

Prototypes and samples available enable you to test the fit and function of the component you want us to make. On the basis of the test results, we can choose the best manufacturing method for your project or make corrections with regard to the design, the material or the shape.